A1 Insignia - Custom Patches & Coins

Australian |  Wholesale |  Low minimum |  Fast turn |

Welcome to A1 Insignia

An Australian veteran owned leading manufacturer of custom patches (Embroidered, Woven, Printed, Chenille and PVC), Epaulettes (rank slides) and Challenge Coins.

We have no setup fees and no digitising fees. All orders are custom made to your specific needs.

All orders are delivered in 10 to 21 days.

A1 insignia supply custom patches and badges nationwide for the military, police, fire departments, security services, sports teams, motorcycle clubs, scholastic awards, commemorative events, and everything in between. We strive to provide you with the highest quality custom products with competitive pricing.

So if you need a custom patch, badge, coin or epaulettes, then drop us an email or give us a call.

MINIMUMS

Our minimum order quantities are as follows:

- Embroidered or printed patches is 25 per design.

- Woven patches is 50 per design.

- PVC patches is 50 per design.

- Challenge coins is 50 per design.

PATCH TYPES

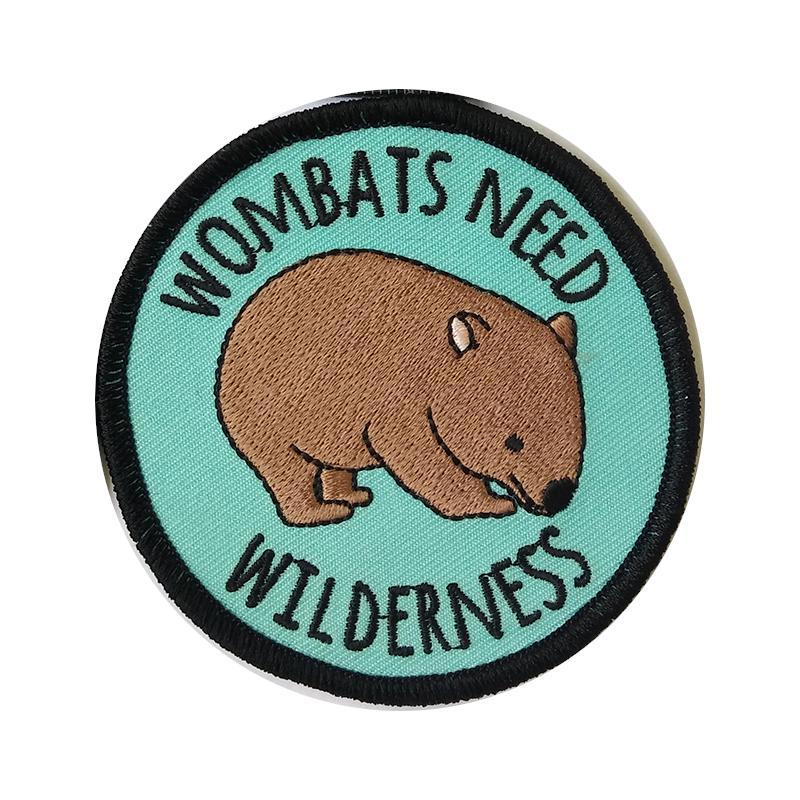

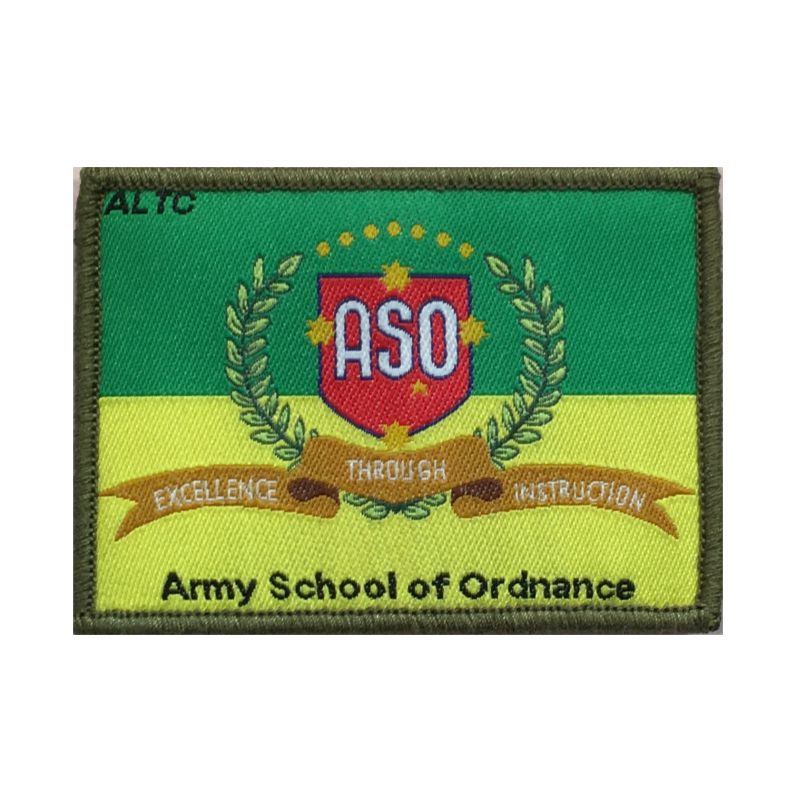

| Embroidered Patches are created using an embroidery machine using materials such as cotton twill base fabric and different colour threads. |

| Woven patches are made of thread only, stitched in a continuous design and achieve finer detail in both the design and text of the patch. This results in a patch that has a smooth appearance with no raised texture. |

| Printed Patches. A computer printer uses heat to directly transfer dye into the fabric to produce a photo-realistic effect. This is the same process used to create photo mouse pads or puzzles. Unlike screen printing, this washable and dry-cleanable image is permanently dyed into the fabric of the patch, not merely painted on its surface. Any image digitally captured can be faithfully reproduced. |

| Chenille patches are a timeless and versatile option, known for their soft, plush texture. These patches are crafted using a special technique of looping yarns over a base fabric, creating a raised, carpet-like surface that exudes a luxurious and tactile feel. |

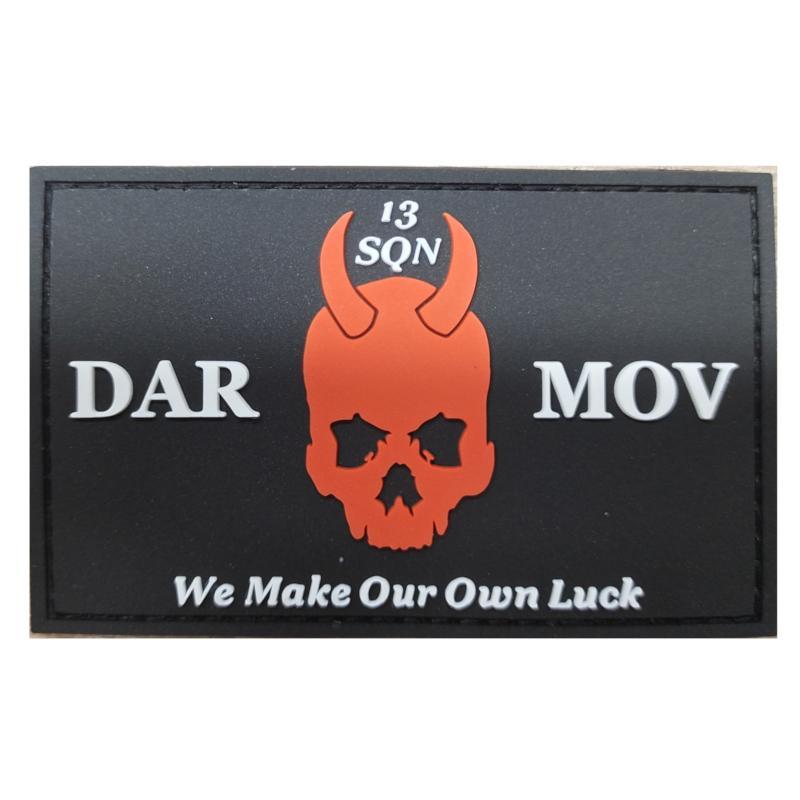

| PVC Patches are made from a type of plastic material that closely resembles rubber. It can easily flex and is highly durable. PVC patches are an excellent choice for outdoor activities because they're not only water-resistant but also highly durable. They are resistant to intense heat and cold without tearing up or popping off your garment! |

BACKINGS

| No Backing – Embroidered patches can be made without a backing. If fact, they start out that way. These patches will show the twill or threads on the backside of the patch, and are generally more flexible. Patches without backings do not have the same thickness or stiffness as patches with backings; therefore, the best occasion to order patches without backings is when they will be sewn onto garments or other types of fabrics. |

| Vilene Backing – Same as above but with a vilene backing which hides the twill or threads on the backside of the patch. This is the standard backing for patches that will be sewn on. (This is our standard backing option) |

| Plastic Backing – Plastic backing adds stiffness and support to the patch allowing it to stay flat over time while still leaving the patch thin enough to be sewn onto a garment. Plastic can be used with any patch, regardless of size, shape, or border type. This is perfect for patches that will be glued onto something. |

| Heatseal Backing – Also known as iron-on, heatseal allows patch application to your garment via home iron. Heat seal backings add some stiffness to patches, allowing them to lay flat. When using heatseal, it is advisable to sew a few stitches to hold the patch in place. Heat seal doesn’t work with nylon, and other synthetic fabrics. (Basically if it will be washed regularly then sew on is better) **see our FAQ page for application instructions** |

| Adhesive Backing – Also known as peel and stick adhesive, turns your patch into an embroidered sticker. Glue is pressed onto the back of the patch, and then is overlaid with paper to be peeled off at the time of use. An adhesive backing is a non-permanent option when applied to fabric or clothing; therefore, it is best for a single event. Although the glue is much stronger than what you will find on an average paper sticker, it will not withstand a cycle in the washing machine, and will also weaken over time. For permanent application, order your custom patches with plastic or no backing and sew them to your garments. |

| Velcro Backing (Hook) – Velcro backings tend to be used in Military applications such as unit shoulder patches, where removing and reapplying patches happen frequently. If your uniform or garment already has a loop fastener area, one-sided Velcro is the best choice. One-sided Velcro is our most popular Velcro option, comprising upward of 95% of Velcro orders. We offer Velcro backing in other colours besides black, including—but not limited to—olive green, black, and light tan. |

| Velcro Backing (Hook & Pile) – If your uniform or garment does not already have a loop fastener area, two-sided Velcro is the best choice. This backing comes with both the hook and loop side. All you have to do is sew the loop fastener to your uniform / bag etc. |

Edge Options

| Overlocked Edge (also known as merrowed edge) – A 3mm border that overlocks the emblem edge, preventing fraying and gives your patch a clean finished look. |

| Embroidered Edge (also known as Satin Stitch) a stitched edge without overlocking the emblem’s edge. |

| Laser Cut Edge the patch gets precisely laser cut or die cut. Laser cut borders can be as little as 1mm. This also make the patches look like direct embroidery. |